Our FRISA Forge company serves a wide variety of industrial markets, offering high-value forging solutions in an extensive range of carbon and low alloy steels, tool steels, medium alloy steels, aluminum, titanium, stainless steels, and superalloys. In addition, our metallurgical experts partner with our customers to provide customized alloy developments to meet their unique needs and requirements.

MARKETS WE SERVE

Oil & Gas

FRISA offers high-quality forging solutions for this fast-paced industry that faces new challenges every day.

Wind Power

We help our customers make the most of their wind turbine platforms and have a positive impact on the environment.

Construction & Mining

Our flexible manufacturing process enables us to deliver a wide range of materials and geometries with quick turnarounds.

Industrial Machinery

FRISA provides reliable parts and high-volume pieces that are vital for the heavy equipment market.

Semiconductors

FRISA offers the best forging solutions in different grades of aluminum and stainless steel for this constantly evolving industry.

WATCH THE VIDEO

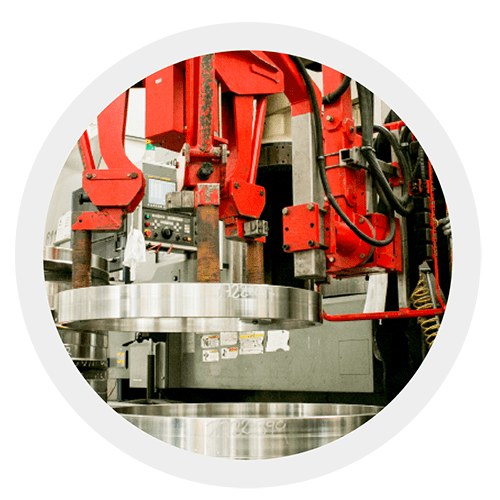

STATE-OF-THE-ART FACILITIES

Our plants specialize in specific forgings and materials using cutting-edge manufacturing equipment and the most innovative technology systems.

TECHNICAL EXPERTISE

Engineering & Metallurgy

Take advantage of our technical know-how. Our team has worked in multiple joint developments, creating solutions to improve performance and reduce costs.

Metallurgic Ph.D. experts on carbon and stainless steels, nickel, and titanium alloys.

Forging engineers for near-net-shape design.

Machining engineers for process design, optimization, and CNC programming.