According to AISI specifications there are nine main tool steel groups: molybdenum high-speed (M), tungsten (T) high-speed, Intermediate high-speed (M), chromium hot-work (H), tungsten hot-work (T), molybdenum hot-work (H), air Hardening (A), high carbon- high chromium (D) and low-carbon mold steels.

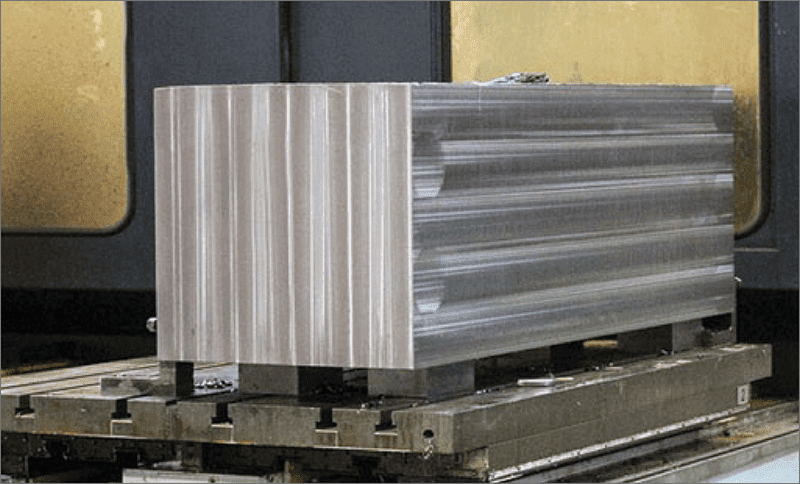

Our top-notch forging technology and capabilities allow us to manufacture custom tool steel forgings into various shapes, including seamless rolled rings, bars, discs, blocks, shafts, and more.

Our top-notch forging technology and capabilities allow us to manufacture custom tool steel forgings into various shapes, including seamless rolled rings, bars, discs, blocks, shafts, and more.

Material grades

Grade |

UNS Number |

DIN |

Werkstoff Nr |

|---|---|---|---|

| H 13 | T20813 | X40CrMoV 5-1 | 1.2344 |

| P20 | T51620 | 40CrMnNiMo8-6-4 | 1.2311 |

| L6 | T61206 | 55NiCrMoV6 | 1.2713 |

INDUSTRIES

ADVANTAGES

High hardness

Abrasion

resistant

resistant

Deformation

resistant

in high

temperatures

resistant

in high

temperatures