Customized steel solutions

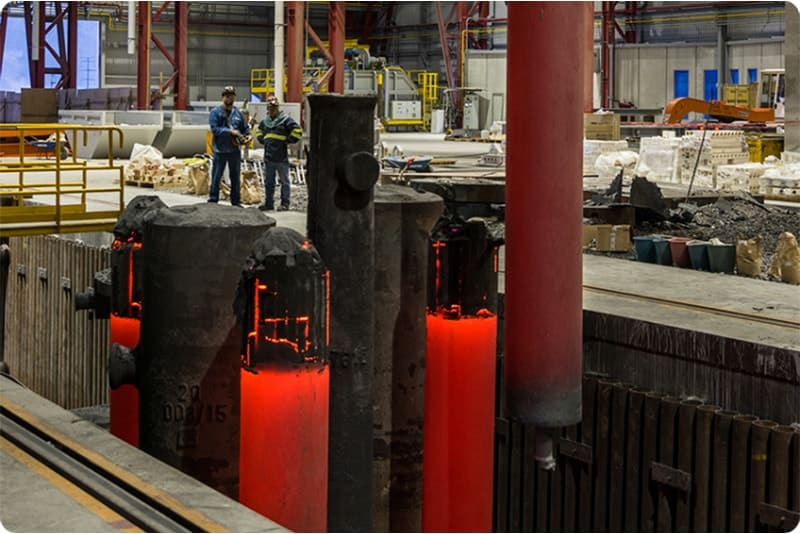

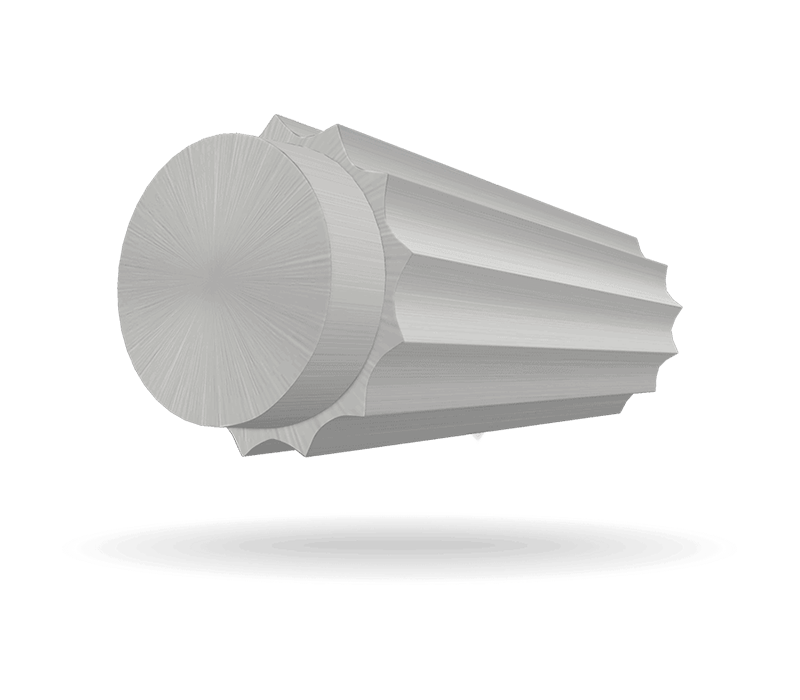

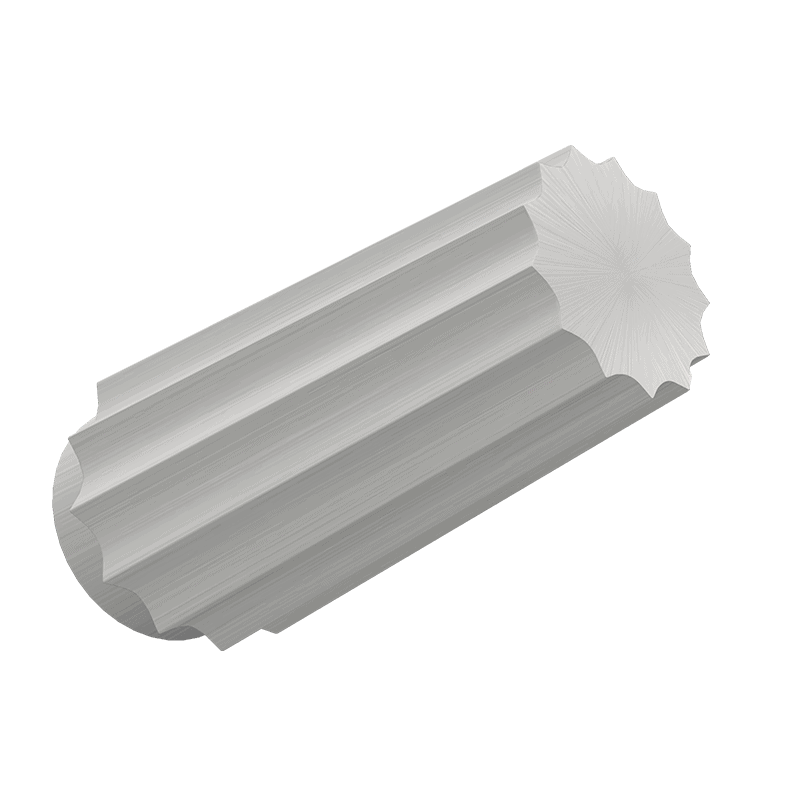

We offer ingots in different grades of steel and alloys to suit your specifications. Our top operational practices and state-of-the-art equipment allow us to offer round, polygonal, and square molds with clean steel, minimum risk of erosion, and precise alignment.

MATERIAL |

RANGEDiameter 13” up to 80” |

WEIGHT RANGEFrom 6,000 lbs up to 127,000 lbs |

BENEFITS

- We offer flexibility in size and weight, plus our ingots can be produced with specific chemistry depending on customers’ needs.

-

We have non-metallic inclusion control.

-

At FRISA, we guarantee high-manufacturing standards, clean steel, and surface quality in every product.