Our FRISA Steel company integrates the best-in-class technologies and excellent operational practices. We provide top-quality steel ingots and forged billets by working closely with steel suppliers such as Vesuvius, Magnesita, RHI, Intocast, Lintorfer, Nuova Fonderia, Autlan, and more.

WHAT WE OFFER

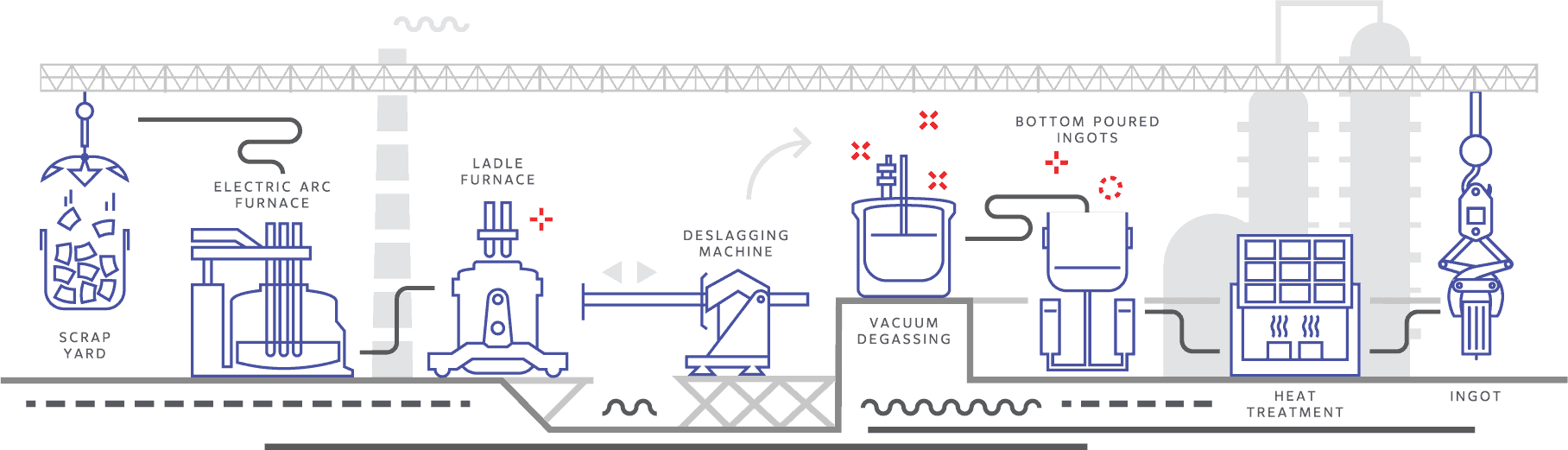

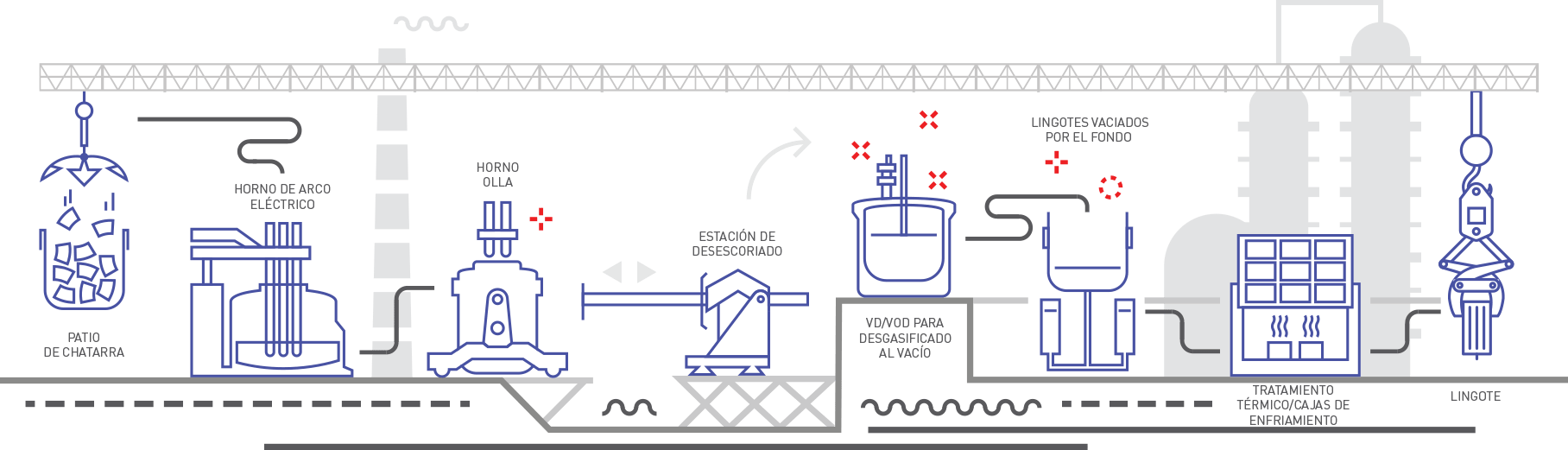

OUR PROCESS

|

WATCH THE VIDEO

STATE-OF-THE-ART FACILITIES

Our new melt shop offers cutting-edge equipment from Austrian company INTECO, experts in specialty steels and ingot casting.

OUR PRODUCTS

Round Ingots

- Diameter sizes from 13” to 39”

- Weight from 6,600 to 55,000 lb

Square Ingots

- Dimensions of 24” and 49”

- Weight from 13,000 to 62,000 lb

Polygonal Ingots

- Dimensions from 52” to 80”

- Weight from 57,000 to 121,000 lb

Rounds or Square Billets

- Dimensions from 8” to 34”

- Weight from 2,000 to 36,000 lb

TECHNICAL EXPERTISE

Frisa Steel combines the experience, technical knowledge, and best-in-class technology to offer our customers high-quality products and services.Heat Treatment

We are equipped a 100-ton capacity cooling boxes and movable furnaces with a maximum temperature of 900 degrees C, and a ramp up to 60 degrees C/h. We provide a variety of treatments, including:- Stress relieving to enable crack-free cooling after striping.

- Soft annealing to reduce hardness and create a specific crystalline structure for easy saw cutting.

- Hydrogen diffusion to avoid internal hairline or shatter cracks, commonly known as hydrogen flakes.

Laboratory

Our cutting-edge laboratory is equipped with the best gear for testing.- Spectro Lab

- LECO CS (carbon and sulfur analyzer)

- LECO ONH (oxygen, nitrogen, and hydrogen analyzer)

- Zetium X-Ray (slag analyzer)

- Phenom XL G2 -Versión PARTICLE X